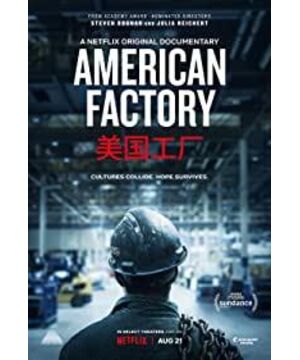

Recently, the documentary "American Factory" (produced by Netflix), produced by the former US President Obama and his wife, has aroused heated discussion on the Internet.

What does the film tell? "Fuyao", China's largest exporter of automotive glass, built a factory in the "rust belt" after the decline of the United States and hired thousands of blue-collar employees. Afterwards, conflicts occurred and gradually began to use AI automation to replace labor in the conflict resolution process. ,gained profit.

This is a new story: it is not the foreign capital and Chinese workers that people are familiar with before, but the Chinese capital and American workers.

Corporate management methods, cultural differences between China and the United States, and new changes in globalization are topics that have been discussed more around "American Factory". The United States was a major manufacturing country in the nineteenth and twentieth centuries. In the 1980s and 1990s, large-scale industrial transfers began to occur. By this century, especially since 2008, it has included Dayton, where Fuyao was founded. There is a wave of factory closures in a number of industrial cities in China. From a production perspective, the unavoidable automation is actually the biggest fatal impact. Even if "Fuyao" provided jobs to Dayton in the early days, no matter how big the difference between Chinese and American employees is, as predicted at the end of the film, automation equipment will become the biggest substitute.

So, are these automated manufacturing industries still the "manufacturing" that we are familiar with? In people’s long-standing traditional impression, manufacturing is the production sector that provides the most jobs. The reason why manufacturing is important is usually not only the need for real economic growth, but also the need for increasing employment rates to achieve a social order.

It is still "manufacturing", but automation is changing the definition. This is a difficult but unavoidable choice.

In the history of human industry, any industrial transformation or reorganization is not calm. Those amazing and gorgeous turns are often just an afterthought. This is obviously a risky process. The risk-bearers include not only business owners and managers who may go bankrupt, but also industrial workers who have been forced to become unemployed and who have been doing this for a long time.

Today, the book reviewer starts with an American story "The Last Day of Parker Pen Company" to feel the impact of the decline of manufacturing on workers. Parker Pen's headquarters is called "Janesville", and the closed factories also include a large automobile assembly plant under General Motors. In the past, the kind of life that allowed a family to live a middle-class life by relying on working in the manufacturing industry has long since faded away. The factory may be moved overseas to build a factory, or it may be fully automated. Now, let's look at the story of American factories from the following three books, the unemployment there, the redefinition of "manufacturing" there, and the appearance of "advanced manufacturing" today.

Original Author | Amy Goldstein and others

origin

The Last Day of Parker Pen Company: An American Story

On the eighth day of 2010, the last part of the Parker Pen Company's assets was liquidated, and the entire factory was moved to Mexico.

The upcoming Friday will be Linda Corban’s last working day. This day came three months after she achieved an important personal goal. In the fall, after a colleague retired, Linda was the most senior of the 153 employees left by the company. It took Linda 44 years to get the first place.

Her relationship with Parker Pen Company began in 1966. That spring, just like every spring at that time, Parker Pen's personnel department went directly to the only high school in Janesville at the time in order to recruit graduates. Parker Pen will hold an agility and speed test, and third-year students can participate as long as they are interested. Most of the participants are girls.

Taking into account the situation in the city at the time, if the lucky boy received the admission notice from General Motors, he would go to the production line; and the lucky girl would go to the neat and friendly factory in Arrow Park if he received the admission notice from Parker Pen. To go to work, manufacturing and assembling pen parts requires skilled movement skills. This is a good job that a woman's hand can do.

Linda took the test. She needs to insert some nails into the board. She is one of the 600 graduates, 20 who can accomplish tasks dexterously, and she was hired. Linda joined her on August 1. 43 years later, she still clearly remembers the thin 18-year-old herself with short golden brown hair. People in the city asked her what job she did. Linda always proudly told On the other side, she is an employee of Parker Pen Company. Giving this answer is an honor in itself.

At that time in Janesville, precious Parker pens or high-quality ballpoint pens were particularly meaningful gifts. The giver was likely to participate in the manufacture by hand, or to make it with others, or at least to know someone from the Parker Pen Company.

Now, her last working day-January 15th-has arrived. It was difficult for Linda to accept—in fact, for many people in the city, the Parker Pen Company’s name would soon become a piece of Janesville’s history.

Before the factory closed, Linda and other colleagues in the inventory department needed to pack the boxes and deliver the extra pens for free. They were sent to a factory in California, a loyal department store in New York, and several other places. Until a colleague in the inventory department asked the person in charge if he could leave some pens here to donate to the food bank, ECHO, the Salvation Army, and even Janesville students.

Who would refuse a beautiful Parker pen? What is left are some elegant ballpoint pens, made of sterling silver, which are also planned to be sent away. A colleague of Linda walked into the office of the top person in charge and suggested that the ladies in the inventory department were the last employees who worked at Parker Pen Company. Don't they deserve a sterling silver pen? On the last day, Linda and the others each got a ballpoint pen.

Linda was 51 years old, single, and needed a job to make ends meet. She never thought of working elsewhere. Therefore, when Sanford, a new employer of Newell Labmate, said that when 65 people were needed to print marks on pens produced around the world, Linda applied. This time, employees will work in a manufacturing workshop located in the northern part of the city, much smaller than Parker Pen. All 65 workers have been carefully selected, just like when she graduated from high school, Linda was honored to be selected.

In the next 11 years, 65 employees increased to 153. Linda still worked in the inventory department. She became the head of the department, which meant that she had to manage and handle the inventory business. Her salary-$18 an hour, is the highest in the factory.

Everything was in order until August 19 last year. Without any warning, Sanford's top head in Janesville came to the factory. In order for everyone to see him, he stepped on a wooden box and announced that the company had decided to close the factory.

Later, a manager of the company's public relations department issued a press release. The article wrote that the Janesville factory was a victim of overcapacity, and a Mexican factory engaged in label printing would take over all the work. "This decision is the company's response to structural problems caused by the rapid changes in market trends," the article continued. "It is definitely not because of dissatisfaction with the outstanding performance of Janesville workers over the years."

For Linda, this is not a structural issue, but a question about people, about the half-century she has experienced. She will soon turn 62 years old. If she leaves now, she can start receiving her pension after receiving the severance pay. Therefore, although she can stay in the factory longer, just like when the Parker Pen Company closed many years ago, she chose to give up and give up her position to younger colleagues so that they can stay for a few more months.

Recognize

What exactly is "manufacturing": a changing concept

"A production department that converts materials, substances or parts into new products through a series of mechanical, physical or chemical processes. As for the assembly of industrial parts, activities other than the construction industry are also considered manufacturing."

This is the definition of manufacturing by the U.S. Census Bureau. This type of definition depicts manufacturing as manufacturing-type production institutions such as factories, facilities, and processing plants that use power-driven machines and material processing equipment as the main means. This involves manufacturing activities that have the characteristics of both machines and humans. . In addition, personal or family workshops that manually transform materials or substances into new products, as well as individuals or families who sell these products directly to the general public, such as bakeries, candy stores, and retail stores, are also included in the category of manufacturing. .

This definition is indeed a bit vague and incomplete, but the most obvious problem is its connotation and boundaries.

In fact, all modern manufacturing industries also involve management, salary and accounting issues, and it is highly dependent on continuous design innovation, research, and real-time transportation of parts and components through various carriers.

Although many products created by modern engineering still have not gotten rid of their ancestors on the surface, the connotation of modern products has undergone tremendous changes. They are a system constructed by a series of parts and services in a completely different way. Automobiles are a typical demonstration of such a dramatic change: Although they are still complex mechanical structures, in modern times, all functions from engine operation to airbag configuration are all realized by computer control, and they require software even more than fighters or fighter jets. The control software of the jet airliner is more complicated.

There is no doubt that a more realistic, objective and inclusive definition of manufacturing is not only statistically significant, but also helps us correctly consider the true performance of the entire category and provides a more valuable basis for formulating industry policies.

The above factors have produced serious consequences.

First of all, it will allow us to limit the manufacturing industry to a deficient definition and cannot extricate itself. It can neither reflect the fact that modern manufacturing is highly mechanized, or even fully mechanized, nor can it reflect the fact that computers and program-controlled equipment are currently being used. Every stage of the manufacturing industry, from design to prototype production, to actual processing, assembly, performance testing, and packaging of the final product, is no exception.

Secondly, when quantitatively evaluating the weight of the manufacturing industry in the entire economy, we often have to resort to artificial limits on the boundaries of the manufacturing industry, but this connotation defect has gradually become a serious obstacle to people's understanding of the manufacturing industry. In the case of large manufacturers outsourcing or subcontracting many or even most of the processes, if there is no large-scale continuous growth in research and development, processing of high-quality special parts, customized assembly, marketing and after-sales covering domestic and foreign markets Services (online operation is now generally implemented), the existence of modern manufacturing is almost unimaginable.

In addition, this phenomenon will become weaker and weaker due to the concept of "origin". Today, even the simplest machinery and equipment may be assembled from parts produced in multiple countries, and the materials and components used to make these parts may also come from different countries. Therefore, any attempt to specify the place of origin is unrealistic. Not only that, if the country of origin is designated as the country where the final assembly process is completed according to the current common practice, this will artificially expand the country’s export volume. In 2009, Andrew Lasweiler's breakdown of Apple's iPhone bill of materials is the best example of this problem.

The key components of the iPhone include memory cards, screens, cameras, transceivers and receivers. These components come from Toshiba in Japan, Infineon in Germany, Broadcom and Numonyx in the United States. Numonyx) and South Korea’s Samsung (Samsung), and the final assembly was completed by Taiwan’s Hon Hai Precision Technology Group through its subsidiary Foxconn in Shenzhen, Guangdong Province. In 2009, the iPhone exported from China to the United States caused the United States’ trade deficit to increase by US$2 billion in terms of total manufacturing costs. However, China’s assembly process costs accounted for less than 4% of the total cost, which means that the value added value created by China has brought less than 75 million U.S. dollars in trade deficit to the United States, and of this 2 billion U.S. dollars , More than 96% of the value has been transferred, of which more than 3/4 of the value comes from Japan, Germany, South Korea and the United States.

future

Why is manufacturing important: "Advanced Manufacturing" that has to be played

The first decade of the 21st century was painful for American manufacturing. Production jobs have fallen by a third, manufacturing output, investment and productivity have fallen, and the trade deficit in manufactured goods has reached worrying levels. A series of market failure problems have emerged: On the demand side, too many manufacturing companies, especially small and medium-sized enterprises, lack the information, resources and knowledge to deploy new models and new technologies to keep up with the pace of foreign low-cost competitors.

On the supply side, large companies, driven by the "asset-light" financial model, have failed to provide support for small companies in their supply chain. With the increasingly weak manufacturing ecosystem, small companies are becoming more and more "lonely".

During this period, approximately 60,000 factories were closed. This directly led to social unrest and severely hit American workers. Later, the industry situation improved, but it was not healthy, and it was still facing deep-seated structural problems.

If the challenges of economic inequality and the creation of high-quality jobs are to be solved, continuous improvement is needed. The key is to drive strong innovation in the manufacturing industry. This will help reverse stagnant productivity levels, increase efficiency, and increase the industry’s response to low foreign wages and Low competitiveness of production manufacturers. Automation and "Advanced Manufacturing".

The American innovation system, as it evolved in the postwar period, is organized around technological challenges outside of manufacturing. After the war, the leading position of the US manufacturing industry has been established, dominating world production, so manufacturing is not a problem. The problem at that time was how to establish a strong "front-end" R&D system to continue the work that had been initiated during the war. Therefore, the American innovation system established mainly during and after the war has never focused on production innovation, but on a series of other technological challenges.

As mentioned above, other countries have not adopted this approach. Germany, Japan, South Korea, and China have organized innovation systems around manufacturing. The United States paid the price for failing to better organize the production innovation system. During the aftershocks of the Great Recession from 2010 to 2015, new manufacturing policies began to emerge. MIT’s “Production in the Innovation Economy” study found that the weakening of the manufacturing ecosystem will not only harm the manufacturing industry, but also endanger the innovation system itself, which is an important comparative advantage of the United States.

The President of the United States nominated a special working group composed of CEOs of manufacturing companies and university presidents, the Advanced Manufacturing Partnership (AMP) group, to imitate the Fraunhofer Institute in Germany and form the Advanced Manufacturing Institute. Develop a series of advanced manufacturing technology paradigms. The 2015 National Academy of Engineering report provided a broader perspective: Advanced manufacturing will integrate services and production, establish a new economic "value" model, and become the core of the future economy. In the end, Congress passed manufacturing regulations and approved manufacturing research institutes and advanced manufacturing projects. At the same time, many competing countries have also begun to formulate their own advanced manufacturing development strategies. The United States has no choice but to continue to promote the development of new advanced manufacturing industries.

Since the Trump administration took office in 2017, it has not yet issued a clear position on the future of manufacturing research institutes. Congress provided full funding for 14 institutions in fiscal year 2017. The government continues to support the strong American manufacturing industry and the new apprenticeship system, but its support for manufacturing research institutes is inconsistent. The government's fiscal year 2018 budget continues to include research institute projects supported by the Ministry of Defense, but as part of the reduction of the Ministry of Energy's budget, it is recommended to reduce the number of research institutes supported by the Ministry of Energy. In order for production innovation projects to continue to have an impact, continuous support and stronger participation from manufacturing research institutes are needed.

In the past, manufacturing was an important employment route for men with high school education, especially white men. However, between 1996 and 2014, the per capita income of white male high school graduates fell by 9%, while the income of white male college graduates increased by 22%. In 2014, the annual income of white male high school graduates was only US$36,787, compared with US$94,601 for college graduates.

Manufacturing jobs are also key to the entry of African-Americans into the middle class in the Midwest and Northeast urban centers, as well as through sectors such as textiles and furniture in the south. The impact of the manufacturing decline has been particularly severe in these regions. Signs of damage to the middle-income class and social inequality are evident in these places. The annual employment rate of men who graduated from high school but did not have a college degree dropped from 76% in 1990 to 68% in 2013. The proportion of men who are not working at all rose from 11% in 1990 to 18% in 2013.

Importantly, the average income of these men fell by 20% between 1990 and 2013. In the fierce 2016 presidential election, it is not accidental that the revitalization of the manufacturing industry has become an important topic. The American dream means more and more economic benefits for everyone. The decline in manufacturing is an important factor in spreading social disappointment and leading to social unrest. The results of the 2016 presidential election reflected this reality.

Stephen Cohen and John Zysman wrote a book called "Manufacturing Is Important" when the manufacturing competition between the United States and Japan reached its peak in 1987. Manufacturing has become more important, especially the "advanced manufacturing" driven by innovation. We can ignore the manufacturing industry and allow it to continue to decline, but it seems to affect innovation capabilities and economic growth, and even social structure and democratic values.

The content of this article is authorized to be integrated from "Janesville", "Made in America", "Advanced Manufacturing" and other books by CITIC Publishing Group, Machinery Industry Press and Shanghai Academy of Social Sciences Press. Integration: Luo Dong. Editor: Xixi; proofreading: Zhai Yongjun. Reprinting is not allowed without written authorization from the publishing house and the Beijing News, and you are welcome to forward it to the circle of friends.

The title picture material comes from the "American Factory" ( American Factory 2019) screen.

View more about American Factory reviews